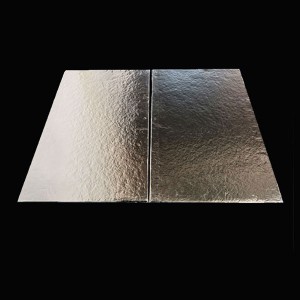

OEM Factory for Custom Insulation Fiberglass Material Vacuum Insulation Panel for Cooler Box

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for OEM Factory for Custom Insulation Fiberglass Material Vacuum Insulation Panel for Cooler Box, We have deep cooperation with hundreds of factories all over China. The goods we supply can match with the different needs. Choose us, and we won’t make you regret!

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for China Insulation and Thermal, glassfiber vacuum insulation panels, With the best technological support, we have now tailored our website for the best user experience and kept in mind your ease of shopping. we ensure that the best reaches you at your doorstep, in the shortest possible time and with the help of our efficient logistical partners i.e DHL and UPS. We promise quality, living by the motto of promising only what we can deliver.

Fiberglass CoreD Material Vacuum Insulation panels vips main advantages:

Maximum Thermal Protection (Low Thermal Conductivity ≤ 0.0025 W/mK)

Thin Design, (2-50mm thickness)

Reduce energy consumption, extent the heat preservation time accordingly.

Reduce the heat loss

Enlarge the inner space

Green Buildings

Excellent sound insulation

Reduce the energy cost

Improve the comfort

Firberglass cored material

About 15 years life span

Glass Fiber Vacuum Insulated Panels Application

Product Details

| Thermal Conductivity [W/(m·K)] | ≤0.0025 |

| Cored Material | Glass Fiber |

| Density [kg/m3] | 250~320 |

| Puncture Strength [N] | ≥14 |

| Tensile Strength [kPa] | ≥100 |

| Compression Strength [kPa] | ≥80 |

| Maximum Size | 1000*1800mm |

| Thickness Range | 2-50mm |

| Size Tolerance for Thickness | ±1mm(<20mm) ±2(>20mm) |

| Service Life [years] | ≥15 |

| Flame-retardant | Level A |

| Working Temperature [℃] | -70~80 |

| Durability (W/m.k) | Increase rate ≤0.001 ( Aging test) |

| Standard Size | 300mmx600mmx25mm |

| 400mmx600mmx25mm | |

| 800mmx600mmx25mm | |

| 900mmx600mmx25mm or customized size |

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for OEM Factory for Custom Insulation Fiberglass Material Vacuum Insulation Panel for Cooler Box, We have deep cooperation with hundreds of factories all over China. The goods we supply can match with the different needs. Choose us, and we won’t make you regret!

OEM Factory for China Insulation and Thermal, With the best technological support, we have now tailored our website for the best user experience and kept in mind your ease of shopping. we ensure that the best reaches you at your doorstep, in the shortest possible time and with the help of our efficient logistical partners i.e DHL and UPS. We promise quality, living by the motto of promising only what we can deliver.