In order to achieve thermal insulation, energy conservation, and a comfortable learning environment. The project utilizes vacuum insulated glass,Fumed Silica Core vacuum insulation panels, and a fresh air system.The application of these advanced materials and technologies can effectively reduce energy consumption and operating costs, and provide a comfortable and healthy learning environment that enhances student learning outcomes and teaching quality. Nanchong High School project will become a socially responsible green building demonstration project, promoting environmental awareness and sustainable development practices.

Area Covered: 78000m² Energy Saved: 1.57 million kW·h/year

Standard Carbon Saved:503.1 t/year CO2 Emission Reduced: 1527.7 t/year

In order to create a comfortable working environment, achieve energy conservation and thermal insulation, and reduce energy consumption and carbon dioxide emissions, This project utilizes products such as vacuum insulated glass, vacuum insulation panels(VIPs), and a fresh air system. it not only can effectively reduce heat loss and energy consumption in buildings, but also can reduce energy expenses and operating costs for businesses and enhancing their competitiveness. This project will become a demonstration project that emphasizes environmental protection and sustainable development, promoting green production and sustainable development practices for enterprises and contributing to the creation of a more livable, green, and low-carbon urban environment.

Area Covered:5500m² Energy Saved:147.1 thousand kW·h/year

Standard Carbon Saved:46.9 t/year CO2 Emission Reduced:142.7 t/year

The project aims to create a comfortable and energy-efficient office environment. To achieve this, the project utilizes products such as metal surface vacuum insulation curtain wall panels,prefabricated modular vacuum thermal insulation wall systems, vacuum glass doors and windows curtain walls, BIPV photovoltaic roofs, photovoltaic vacuum glass, and a fresh air system. Utilizing these innovative technologies, the project can achieve the effect of ultra-low-energy consumption buildings, reduce energy consumption and carbon dioxide emissions. At the same time, these technologies can also improve indoor air quality, creating a healthier and more comfortable working environment. This project is a typical sustainable building, providing useful examples and references for other buildings.

Area Covered:21460m² Energy Saved:429.2 thousand kW·h/year

Standard Carbon Saved:137.1 t/year CO2 Emission Reduced:424 t/year

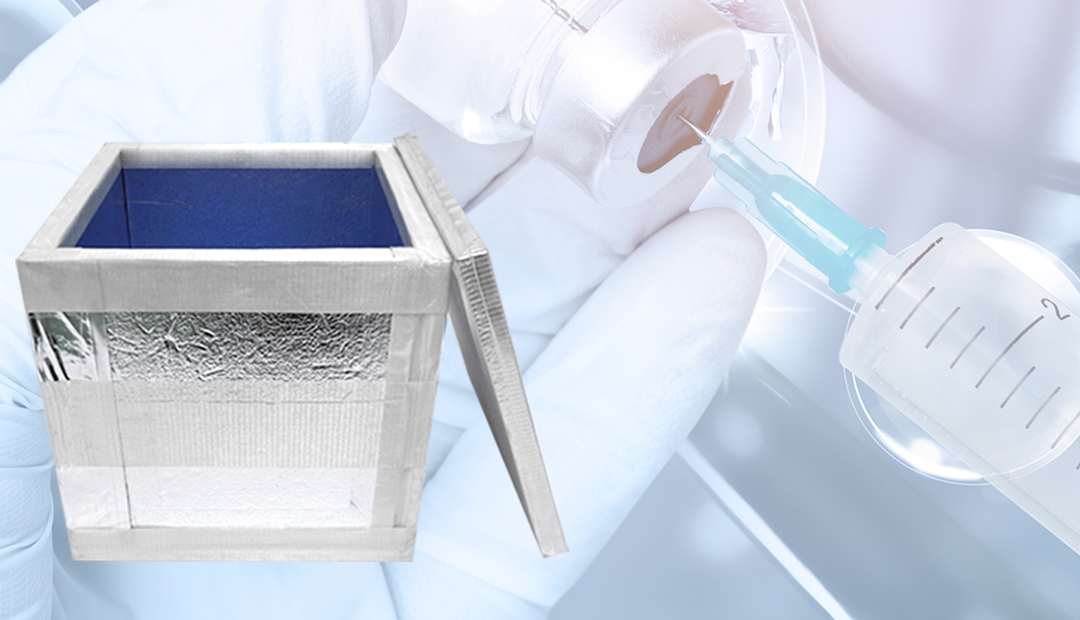

The Vaccine Insulation Cooler Box project uses the Fumed Silica Vacuum Insulation Panel technology (Thermal conductivity ≤0.0045w(m.k)) to provide a super-low temperature environment for the storage and transportation of vaccines. This insulation box not only maintains a stable low temperature environment, but also has insulation performance, which can effectively protect the vaccine when the ambient temperature changes. By using Vacuum Insulation Panel technology, the storage and transportation costs of vaccines can be reduced, and also improve the quality and efficacy of vaccines, which makes an important contribution to global public health. This vaccine insulation cooler box project provides vital support in the fight against the pandemic.