As demand for ultra-low temperature vaccine transport surges, companies are seeking innovative solutions that are not only super energy-saving but also lightweight, space-saving, and easy to transport. In recent years, fumed silica cored material has emerged as a game-changing technology in the field of vacuum insulation panels (VIPs). Today we will explore the cutting-edge VIPs technology and how Zerothermo is leading the way in providing the best products for cold chain logistics. VIPs, known for their high performance in thermal insulation, are made up of an evacuated space between two metal sheets, with the space being filled with a core material. The core materials used in VIPs range from open-cell foam to glass fiber, but currently, the most promising core material for VIPs is fumed silica. This material is lightweight, super thin, and has super insulation benefits. It's an ideal solution for industries that require insulation with no added weight or space constraints.

One of the most significant applications of VIPs is for cold chain logistics, which involves maintaining ultra-low temperatures during the transport of pharmaceuticals and vaccines. However, traditional insulation materials, such as polystyrene foam and polyurethane foam, have limitations in terms of space, weight, and insulation performance. VIPs, on the other hand, have the potential to revolutionize cold chain logistics, making ultra-low temperature transport more efficient and environmentally friendly.

Zerothermo is a market leader in VIPs technology. The company's VIPs are made by a unique vacuum suction method, which makes them more efficient and helps maintain a longer shelf life. With over 20 years of experience in vacuum technology, Zerothermo has a vast team of 330 R&D engineers and over 1100 employees working to improve the technology further. Additionally, the company has two high barrier laminated film packing production lines and six production lines of fumed silica core vacuum insulation panels making it one of the largest production facilities in the world.

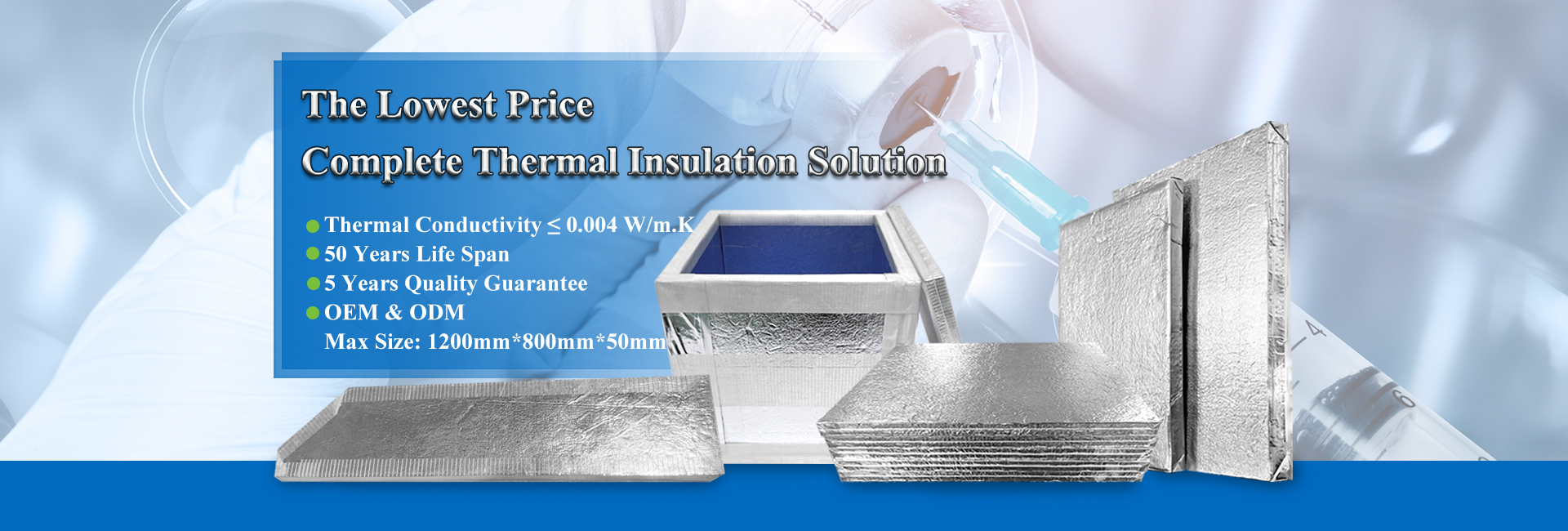

The VIPs produced by Zerothermo have a thermal conductivity coefficient as low as 0.004W/m.K, which is only one-tenth of that of traditional insulation materials. This outstanding insulation performance enables the safe and efficient transportation of ultra-low temperature pharmaceuticals and vaccines. Additionally, VIPs produced by Zerothermo are easy to manage, store, and install.

the VIPs technology made with fumed silica cored material is a game-changing innovation in the world of thermal insulation. It provides an eco-friendly, sustainable, and efficient solution for cold chain logistics. Zerothermo is at the forefront of this technology, continuously improving it to ensure that it meets the ever-increasing need for ultra-low temperature transport. If you're in the market for cold chain logistics solutions, contact Zerothermo to learn more about how their VIPs can benefit your business.

Zerothermo focus on vacuum technology for more than 20 years, main products: vacuum insulation panels, vacuum insulated glass, high temperature nano microporous panels, flexible insulation blanket mat. Zerothermo is committed to quality, innovation, and customer satisfaction makes them a trusted partner for businesses looking for reliable and efficient thermal solutions.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: May-22-2023