Pharmaceutical products, especially vaccines, require a cold chain to maintain efficacy. It means that from the time they leave the manufacturing unit until they reach their final destination, they must be transported and stored under cooling conditions. Inadequate temperature control may render the vaccine unusable, costing time, money, and even lives.

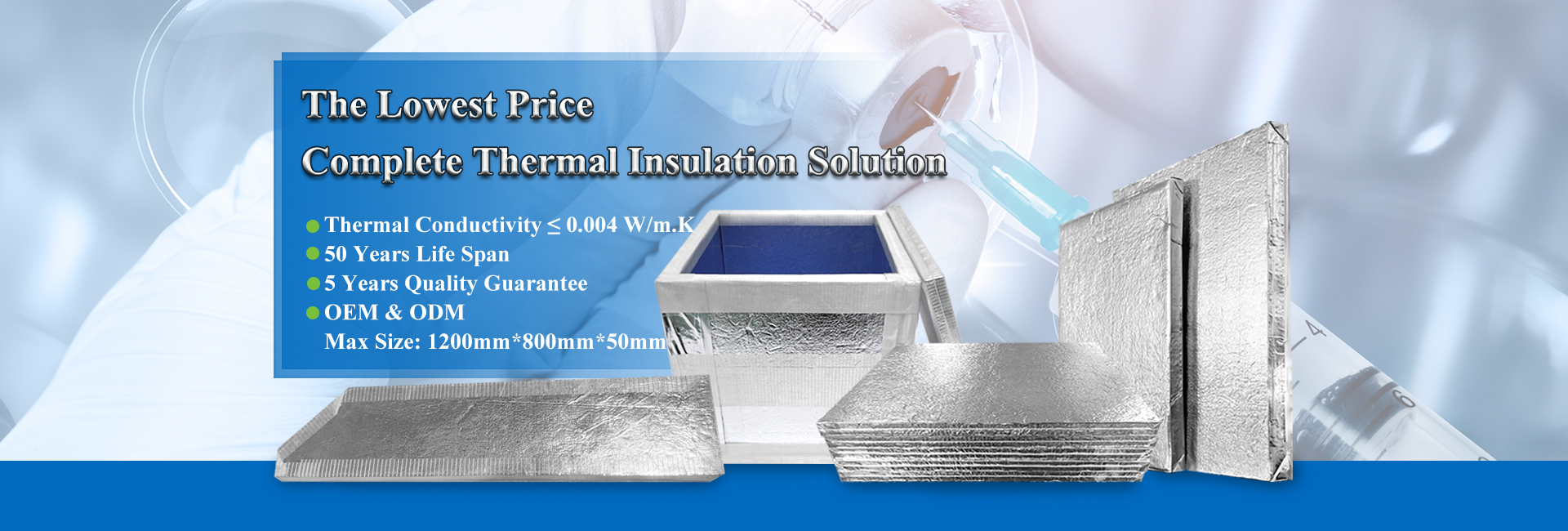

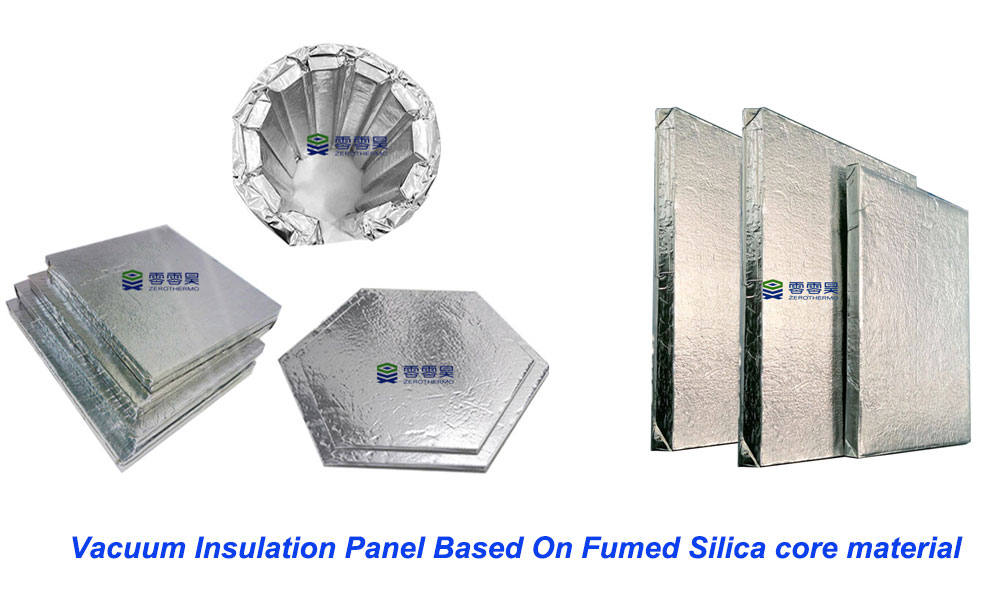

To ensure that vaccines remain viable and effective, Zerothermo company has produced Vacuum Insulation Panels VIPs for Pharmaceutical Cold Chain Insulation Boxes. VIPs incorporate Fumed Silica Cored Material and offer specific advantages over traditional insulation materials.

Zerothermo is located in Sichuan and has been focusing on vacuum technology for over 20 years. The company has 330 R&D engineers, 1100 employees, and six production lines that produce fumed silica core vacuum insulation panels. These panels have high thermal insulation property and are ideal for ultra-low temperature vaccine storage and transportation.

One of the main advantages of VIPs for cold chain insulation is their high insulation efficiency with minimum material thickness. The core material - fumed silica - has an extremely low thermal conductivity that results in excellent insulation performance. The vacuum insulation panel layers trap air molecules and prevent heat transfer, thus ensuring the temperature is stable, regardless of external temperature fluctuations. Traditional insulation materials such as expanded polystyrene, polyurethane foam, and fiberglass are not as effective as VIPs when it comes to preventing heat transfer. Expanded polystyrene has a high thermal conductivity and is prone to breakage, while polyurethane foam is not waterproof and may become brittle over time.

Another advantage of VIPs for cold chain insulation is their low weight and thickness. Compared to traditional insulation materials, VIPs weigh less and create less bulk, which makes them ideal for mobile applications such as vaccine transportation. Since vaccines have to be transported to remote locations, VIPs' portability is essential for maintaining the cold chain. VIPs are environmentally friendly and do not use any hazardous chemicals during production. They can be recycled easily, making them sustainable for green initiatives.

VIPs with fumed silica cored material are the most viable solution for pharmaceutical cold chain insulation. Zerothermo vacuum insulation panel production technology and experience will guarantee VIPs' quality and reliability over their service life. VIPs ensure that vaccines reach their intended destination in optimal condition and play an integral role in public health protection.

Zerothermo focus on vacuum technology for more than 20 years, main products: vacuum insulation panels, vacuum insulated glass, high temperature nano microporous panels, flexible insulation blanket mat. Zerothermo is committed to quality, innovation, and customer satisfaction makes them a trusted partner for businesses looking for reliable and efficient thermal solutions.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Jun-06-2023