The emergence of fire has played a great role in promoting the development of human civilization. The use of fire can be said to be a groundbreaking revolution in human energy use, and its essence is a way for human to master the use of heat energy. With the passage of time and the development of science and technology, people are more and more aware that the development of sustainable clean energy and energy saving will be a major issue that human beings need to face in a considerable period of time. For energy conservation, of course, the best way is not to reduce the use of energy, but how to improve the efficiency of energy use is the core of the problem. In the field of low temperature, starting from the scientific basis of heat conduction, we have found the best solution for heat insulation and insulation at present - vacuum insulation panels is the best insulation and insulation material in the field of low temperature.

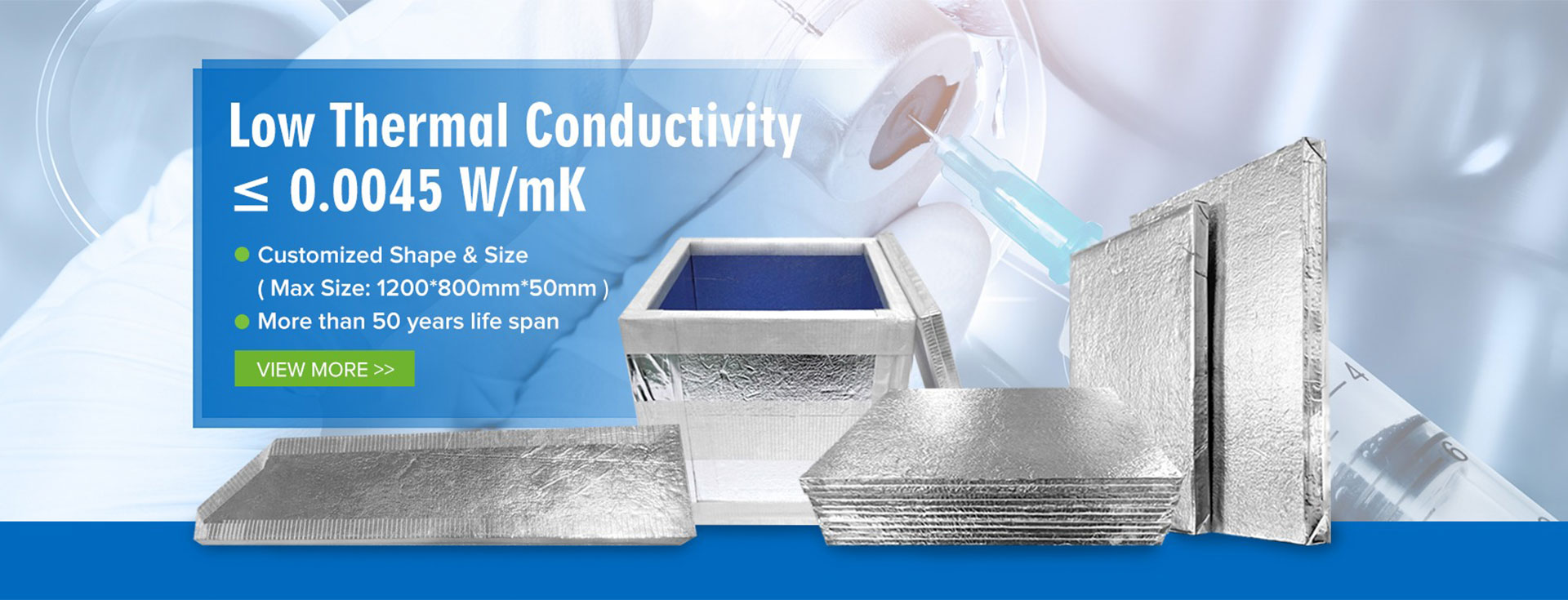

Vacuum Insulation Panel (VIP) is a new type of super insulation material based on vacuum insulation technology. It combines the advantages of vacuum insulation and microporous insulation, so the insulation effect has reached the extreme. VIP is made of porous nanocore material with good thermal insulation performance and sealed with high barrier film under vacuum condition, which minimizes heat conduction, heat convection and heat radiation, and isolates heat transfer, with high thermal insulation capacity. The core material of vacuum insulation board is made of nano-porous material, which has very high insulation property. After vacuum packaging treatment, the overall thermal insulation performance is greatly improved. Its thermal conductivity is as low as 0.005W/(m·K), thermal insulation performance is equal to 8 times of rock wool, 5 times of foam polyurethane, 4 times of aerogel. At present, vacuum insulation board has been widely used in building exterior insulation, cold chain insulation, pharmaceutical vaccine insulation, refrigeration equipment insulation and other industries, to help reduce energy consumption, energy conservation and emission reduction.

In the field of High Temperature Nano Microporous Panel, because the high temperature environment has higher requirements for the resistance of thermal insulation materials, the material encapsulation layer is often vulnerable to damage under the great temperature difference. Therefore, in the field of high temperature insulation, more work is done on nano thermal insulation materials, rather than vacuum packaging. At present, High Temperature Nano Microporous Panel are mainly made of vapor silica, mixed with special inorganic binder, sunblock, etc., and high temperature resistant fiber. Gaseous silica is the halide of silicon, which is hydrolyzed at high temperature in the flame of hydrogen and oxygen. It is an amorphous silica product with a primary particle size between 7~40nm. The nanoscale pore network structure and thermal barrier components not only eliminate convective heat transfer, but also greatly reduce the thermal conductivity of the material and high temperature thermal radiation, so that the thermal conductivity of the material at the hot surface temperature of 800 degrees Celsius is 0.03W/(m·K) lower.

The thermal insulation performance of high-temperature nano-porous insulation materials has more significant advantages than that of traditional materials. After reaching the required range of thermal insulation, the thickness of insulation layer can be greatly reduced. In addition, high temperature nano-porous insulation material can withstand the high temperature of 1100 degrees Celsius, with strong flame retardant, at the same time, the thermal conductivity with the increase of temperature is low, low shrinkage rate. High temperature nano-porous insulation materials are suitable for high temperature insulation in a variety of scenarios, including a variety of power stations, cement plants, glass plants, metal smelting, petrochemical, new material manufacturing and other fields that need to use high temperature kiln, reactor or high temperature environment. The use of high temperature nanoporous insulation materials can better achieve heat preservation and insulation, reduce heat loss in high temperature reaction, save energy, and help achieve cost reduction and efficiency, energy saving and emission reduction in many important industrial production fields.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Nov-29-2022