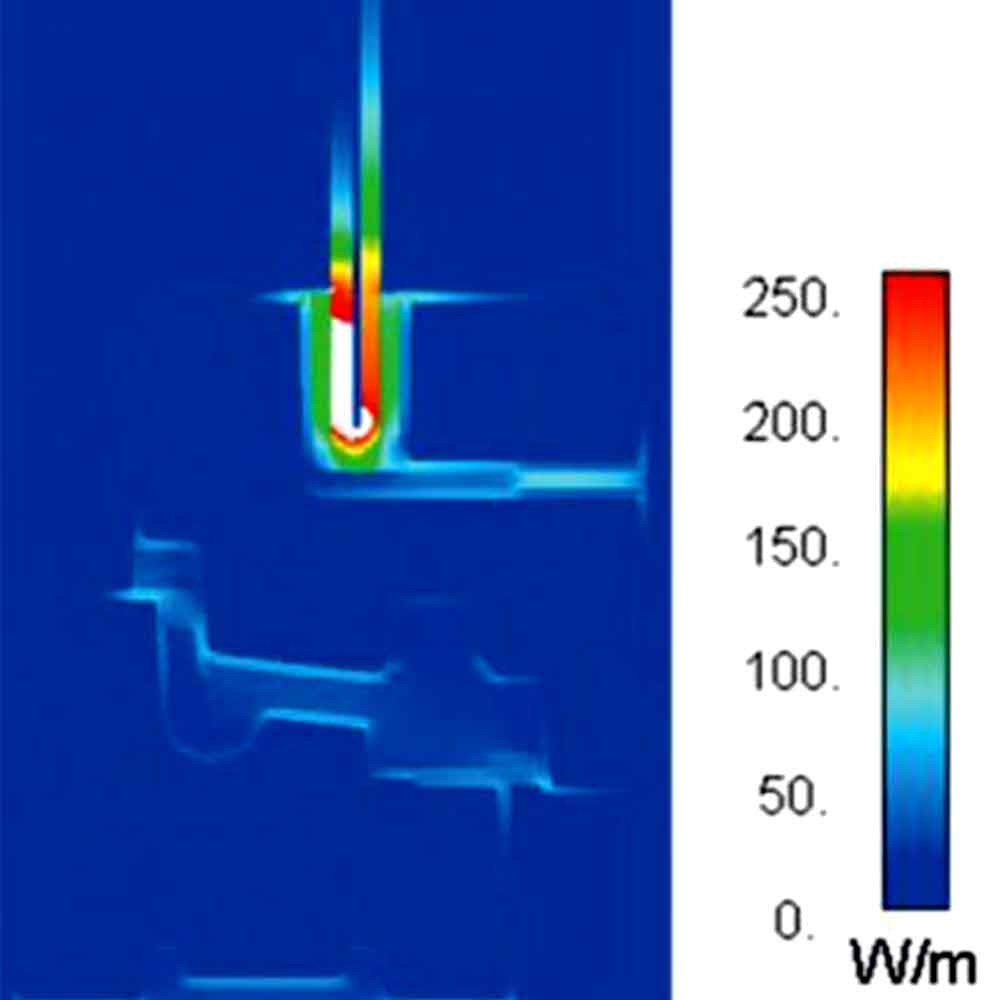

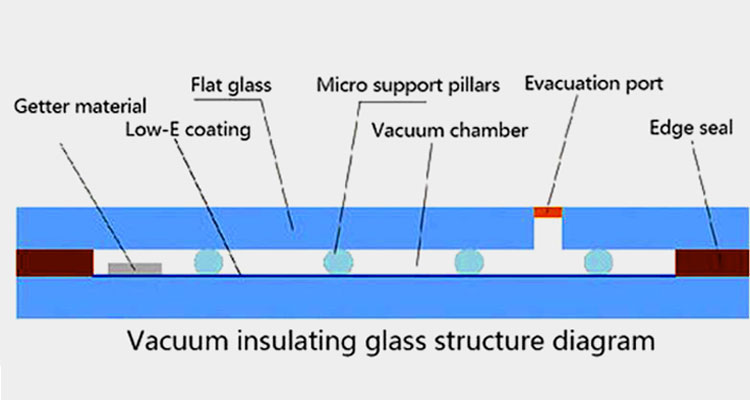

Compared with insulating glass, vacuum insulated glass has better thermal insulation performance. Heat is transferred in three ways: conduction, radiation, and convection. Among them, heat conduction needs to pass through the medium, and it can be considered that there is almost no medium in the vacuum layer, so that the heat conduction is minimized. The vacuum insulated glass only conducts heat at the edge, and its main section is almost completely insulated. The heat transfer coefficient Ug value of vacuum insulated glass can be easily achieved below 0.5W/㎡, while the heat transfer coefficient Ug value of three-glass two-cavity insulating glass reaches 0.7W/㎡K, which is close to the limit. Because of the excellent thermal insulation performance of vacuum insulated glass, in severe cold regions, even in the case of extremely low temperature outdoors in winter, the temperature of the inner surface of the glass can still be maintained above the dew point temperature, thus effectively preventing condensation.

Vacuum insulated glass has better light transmission performance. In order to reduce the heat transfer coefficient of glass, the thermal insulation and energy-saving glass used in buildings is Low-E glass, also known as low-emissivity glass. The surface of the glass is coated with Low-E film, which is a film-based material composed of multi-layer metals or compounds, which can reflect infrared radiation, thereby effectively reducing indoor radiation heat dissipation in winter. But there are advantages and disadvantages.

The Low-E film can not only reflect infrared rays, but also reflect visible light, which will lead to a decrease in the light transmission performance of the glass. In order to have better thermal insulation performance, three-glass two-cavity insulating glass often adopts a double-layer Low-E structure, resulting in the visible light transmittance τv value of the glass often being lower than 0.6. The vacuum insulated glass only uses single-layer Low-E, which can achieve a lower heat transfer coefficient than double-layer Low-E insulating glass, and the visible light transmittance τv value can reach more than 0.8.

It is self-evident that the air-borne sound insulation performance of vacuum glass is superior. The transmission of sound waves needs to pass through the medium, so the vacuum glass can effectively block the noise, and its weighted sound insulation can reach more than 40dB, while the insulating glass is only about 30dB.

The working vacuum degree (≤0.1 Pa) in the vacuum layer can be kept for a long time, which determines the service life of the vacuum glass. International manufacturers such as Asahi Glass can provide a 15-year warranty for vacuum glass products in Europe and Japan, and the actual expected service life is more than 25 years. With the advancement of technology, the process has gradually matured, and the domestic vacuum glass technology has reached the world's advanced level. Since the inert gas in the insulating glass will gradually leak over time, this determines that the insulating glass also has a service life problem.

Compared with insulating glass, vacuum insulated glass is lighter and thinner. The thickness of the hollow layer of insulating glass is usually 6~12mm, or even thicker, and the interior is filled with air or inert gas, while the vacuum layer of vacuum glass is only 0.1~0.2mm. In addition, the vacuum glass with a layer of vacuum layer sandwiched between two glasses, its thermal insulation effect can be compared with the three-glass two-cavity insulating glass, and because one layer of glass is used less, its weight is reduced compared with the three-glass two-cavity insulating glass 1/3

For the glass door and window project equipped with broken bridge aluminum windows, we propose a new exterior window renovation plan: retain the original window frame, replace the original double-layer insulating glass with poor thermal insulation performance with vacuum glass, and replace the sealing strip. The advantage of this solution is to avoid the need to replace the entire window, or add a layer of external windows, etc. The amount of work is large, which will adversely affect the normal life of the residents, so it is difficult to implement large-scale renovation measures. Of course, this solution needs to meet certain prerequisites: the original window frame profiles are of good quality and are still worth keeping. Because the effect we want to achieve is to undergo energy-saving renovations. After the old exterior windows are replaced with vacuum glass, they will continue to be used for at least 15 years, instead of being completely dismantled and replaced in just a few years after the renovation, resulting in unnecessary waste.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Nov-22-2022