China OEM Ice Pack For Cool Box - Building heat shield materials thermal wall vacuum insulated panel – Zerothermo

China OEM Ice Pack For Cool Box - Building heat shield materials thermal wall vacuum insulated panel – Zerothermo Detail:

Product Features

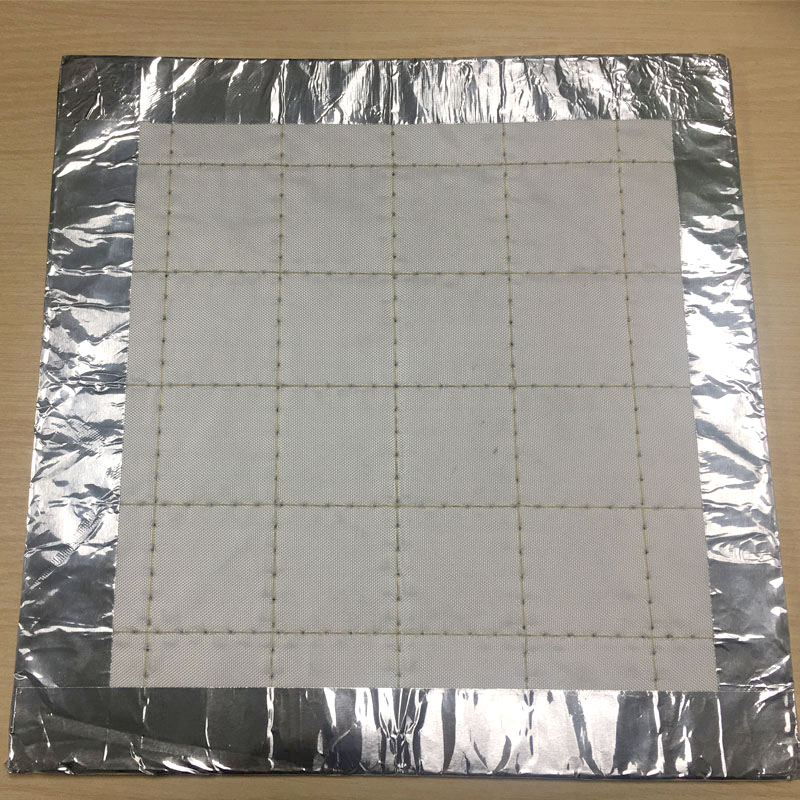

Fumed silica VIP is consisted of a unique combination, mainly on fumed silica, a nano-porous silica materials. And all the components are highly recyclable.Also fumed silica VIP panels insulate performance up to ten times better than conventional insulation materials.

The VIP’s performance is a result of the inner vacuum. In a vacuum, heat can not travel through the air by conduction or convection. This limited ability for heat to travel in the vacuum is what gives vacuum insulation panels such a high thermal insulating performance and R-value.

Product Details

| Thermal Conductivity [W/(m·K)] | ≤0.008 |

| Thermal Resistance [m·K/W] | ≥4 |

| Density [kg/m3] | 180~240 |

| Puncture Strength [N] | ≥18 |

| Tensile Strength [kPa] | ≥100 |

| Compression Strength [kPa] | ≥100 |

| Surface Water Absorption [g/m2] | ≤100 |

| Expansion Rate After Being Punctured [%] | ≤10 |

| Thermal Conductivity After Being Punctured [W/(m·K)] | ≤0.025 |

| Service Life [years] | ≥50 |

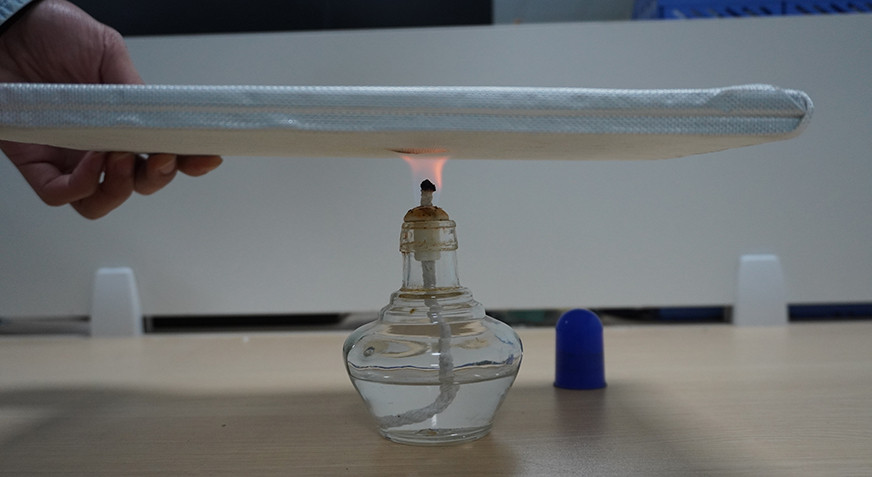

| Fire Resistance | Grade A |

| Working Temperature [℃] | -70~80 |

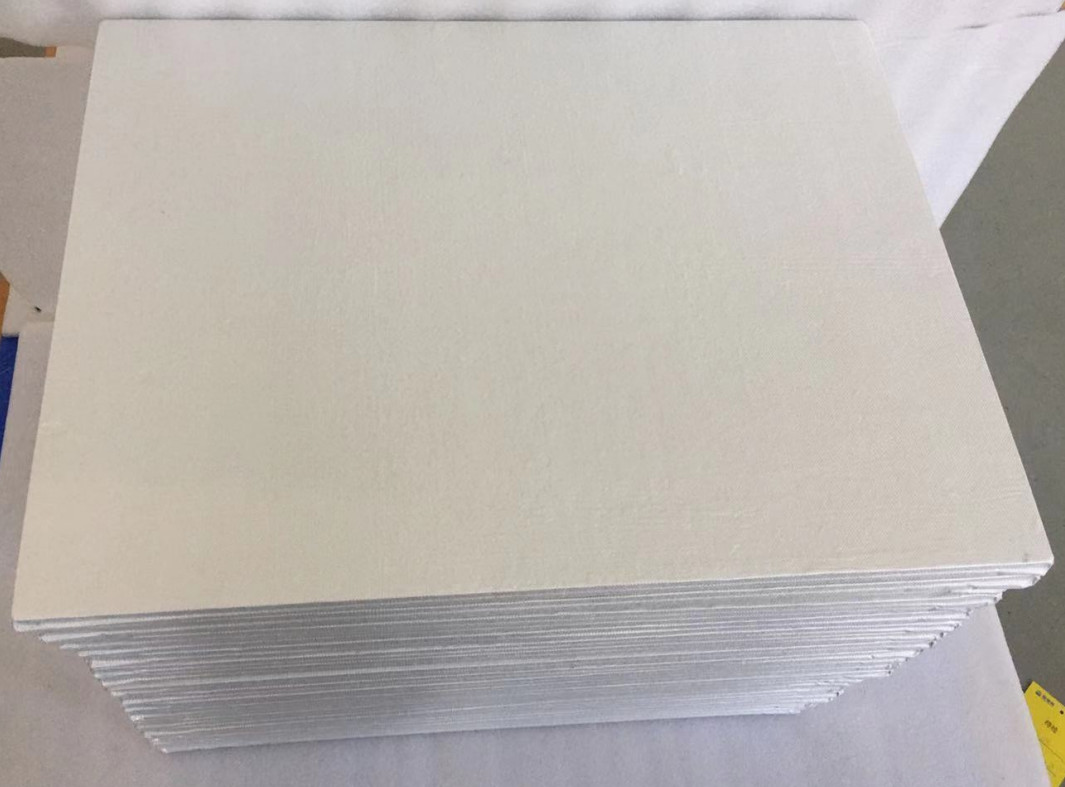

| Size | 300mmx600mmx25mm |

| 400mmx600mmx25mm | |

| 800mmx600mmx25mm | |

| 900mmx600mmx25mm or customized size |

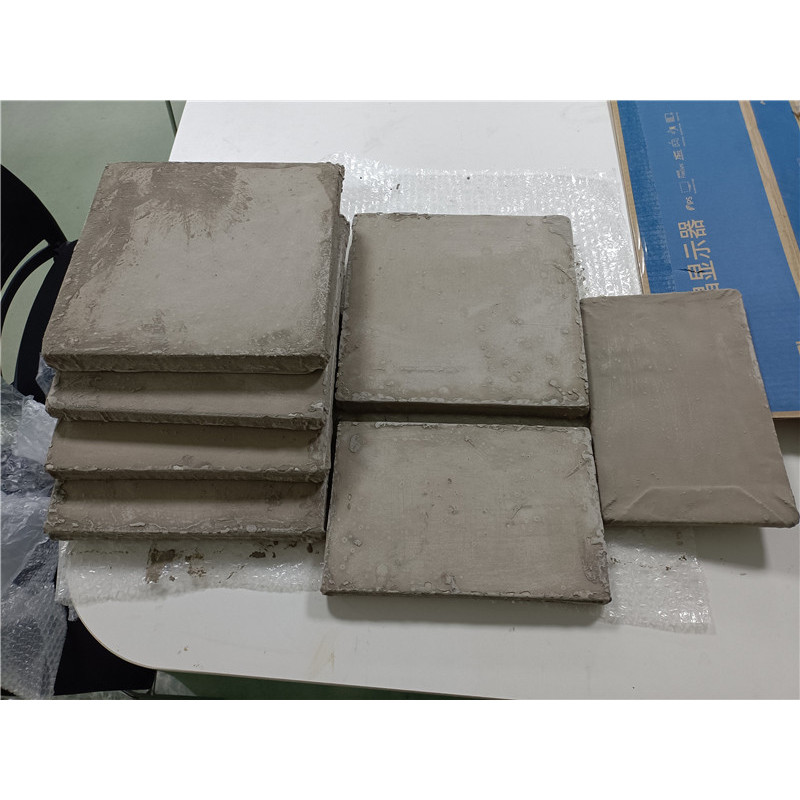

Product Processing

Core material mixing, core producing(Mold Type), core cutting(cutting to customer request size),core packing with non-woven envelop, core drying(removing moisture and debris),vacuum process,first test and leakage inspection, flaps folding,leakage inspection by standing,all test,carton packaging.

Supply Ability:50000 Square Meters per Month

Packaging Details:Strengthened Carton on Pallet

Loading Port: Shanghai, Shenzhen, Guangzhou

Application: building wall, floor, roof

Business Conditions and Terms:

Prices and Delivery Terms: FOB, CFR, CIF, EXW, DDP

Payment Currency: USD, EUR, JPY, CAD, CNY, AUS

Payment Terms: T/T, L/C, D/P D/A, Western Union, Cash

Product detail pictures:

Related Product Guide:

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for China OEM Ice Pack For Cool Box - Building heat shield materials thermal wall vacuum insulated panel – Zerothermo, The product will supply to all over the world, such as: Stuttgart, Malta, Jersey, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we have better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We are always here working for your demands whenever you need.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!