A safe and complete cold chain system, after harvesting ingredients from the origin, needs to go through various links such as pre-cooling, processing, low-temperature storage, refrigerated transportation, distribution, etc., and finally delivered to consumers. During the entire cold chain storage and transportation process, fresh food has strict requirements on temperature control.

Temperature variation have an irreversible impact on the quality of fresh food. Once the temperature fluctuation exceeds the optimal storage temperature of food, microorganisms will multiply, and the nutritional quality of fresh food will be accelerated, and food safety and quality issues will face severe challenges.

In the cold chain investment, the highest proportion is cold storage and refrigerated trucks, which are the core facilities in the cold chain. Among the many factors that affect cold storage and refrigerated trucks, the selection of thermal insulation materials is the key to controlling temperature changes.

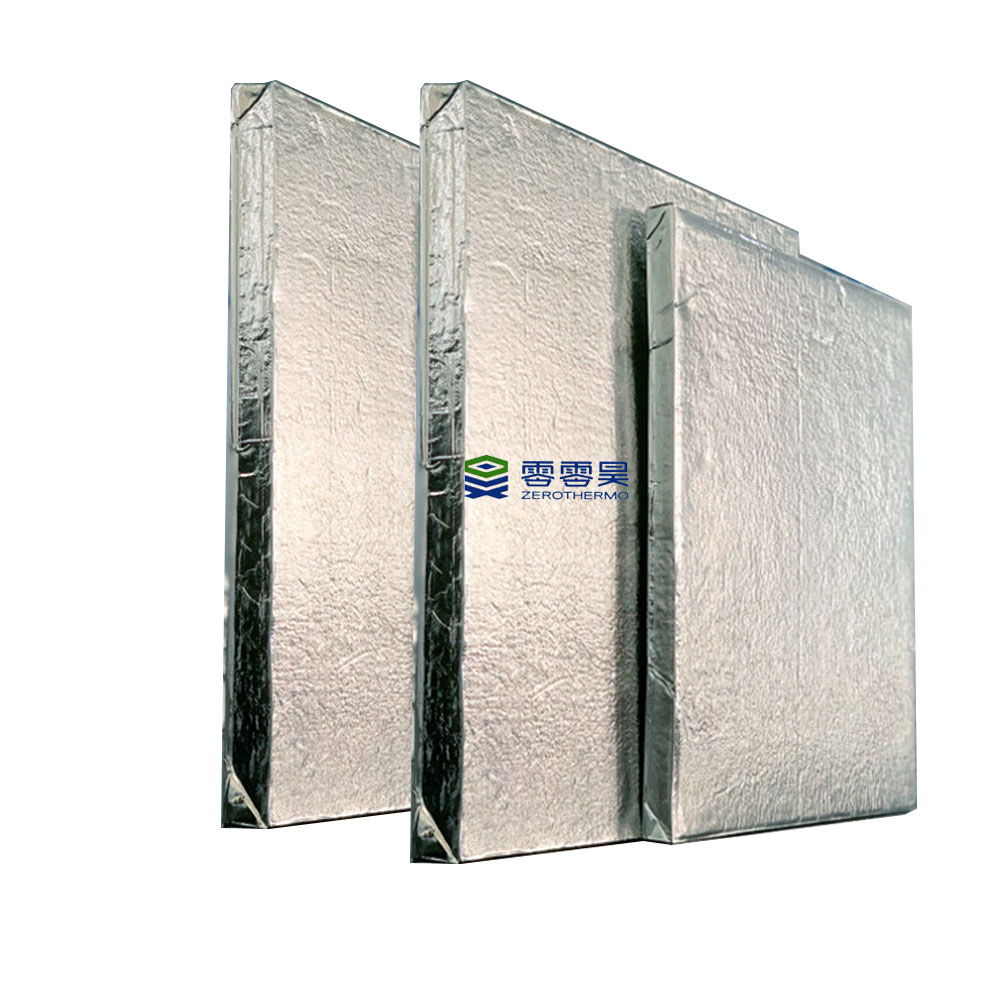

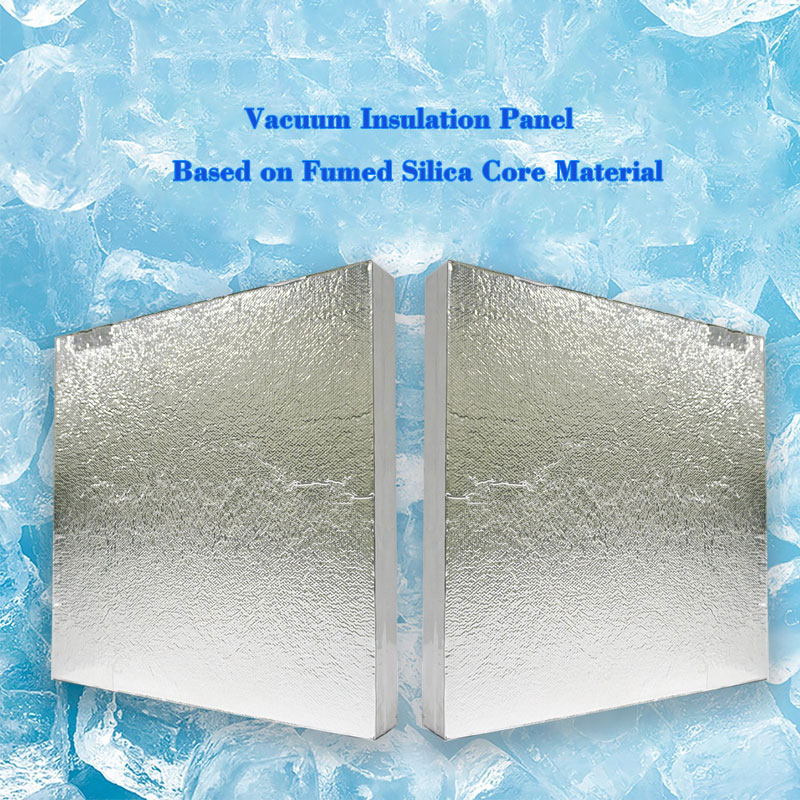

VIP vacuum insulation panel is a kind of cold chain insulation material, which is professionally used in the cold chain industry. The panels mainly uses fumed silica as cored material, vacuum barrier film as the gas barrier material, and also it is an industrial thermal insulation material made of high vacuum through a vacuum packaging machine. It is currently the world's most advanced and efficient thermal insulation material.

Food safety is no trivial matter, fumed silica vacuum insulation panels ensure food safety and hygiene to a large extent through stable heat insulation performance and long service life, creating a cold chain safety system that is exclusive to you.

Vacuum Insulated Panels (VIP board) Main Advantages

1. The thermal conductivity is below 0.0045W/(m·K), fumed silica cored material, and it is currently the best thermal insulation material;

2. The high-efficiency inorganic vacuum insulation panel can reduce the thickness of the insulation layer, reduce the volume of the object, and increase the storage space.

3. Excellent durability, lifespan is more than 50 years;

4. Good stability, which can effectively ensure the thermal insulation effect;

5. Flexible size(5-50mm), light weight and easy installation;

6. Safe and environmentally friendly, making a huge contribution to environmental protection and national energy conservation.

Scope of application VIP vacuum insulated panels are mainly used for thermal insulation, such as household refrigerators, yacht refrigerators, mini refrigerators, car refrigerators, cryogenic freezers, electric water heaters, vending machines, freezers, refrigerated containers, building wall insulation and transportation.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale manager: Mike Xu

Phone :+86 13378245612/13880795380,

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Sep-29-2022