Environmental protection and energy saving have become the theme of the current world economic development, the development of an energy-saving environmental material has become the urgent need to alleviate the energy crisis, Vacuum Insulation (VIP) should be timely, has been widely used in refrigerators, refrigerated containers, construction and other fields. VIP is a kind of vacuum insulation material based on the vacuum insulation mechanism. It is mainly composed of three parts: the core layer porous medium insulation material that is vacuumed, the air insulation structure used to isolate the core material from the outside world and the gas adsorption material. The heat insulation is realized by maximizing the vacuum degree of the core material. However, how to ensure the thermal stability and long-term effectiveness of VIP in the whole system life cycle has become the most concerned topic of many researchers and users

Vacuum insulated panel has good thermal insulation performance, which provides an effective thermal barrier for energy saving, especially in the field of construction. However, its service life has become the key issue that many researchers, manufacturers and users are most concerned about. Air insulation structure is an important component to maintain the vacuum degree in vacuum insulated panel, and its performance has a great influence on the thermal performance and service life of vacuum insulated panel

In fact, the thermal conductivity of VIP is not constant, with the passage of time in the use of thermal insulation occasions, the outside gas through the insulation structure into the panel, so that its thermal insulation performance attenuation, thermal conductivity and then rise. Air insulation structure is an important part of VIP, which is mainly used to form a certain closed space, prevent the penetration of external air and water vapor, maintain the internal vacuum degree of the core material to maintain the adiabatic performance of VIP, so its air resistance performance is the most important factor affecting the vacuum degree and service life of VIP. Early VIP mostly uses extremely thin stainless steel as an air insulation structure, but because of its easy to cause large edge thermal bridge effect and gradually replaced by composite film.

Air insulation membrane is one of the important components of VIP, and its performance has great influence on the adiabatic performance and stability of VIP. As an indispensable part of the structural membrane, the aluminum foil has good air blocking performance. VIP air blocking structural membrane should contain at least one layer of 7μm aluminum foil. As a barrier to maintain the vacuum degree in VIP, the air insulation structural membrane can also cause thermal bridge effect. The thickness of the metal layer should be selected in combination with the boundary thermal bridge effect, the use environment, the process and service life of the VIP carrier system. The service life of VIP is not only related to the gas insulation structure membrane, but also related to the physical properties of the core material, the degree of vacuum in the panel, whether there is gas adsorption material, the use environment, etc.

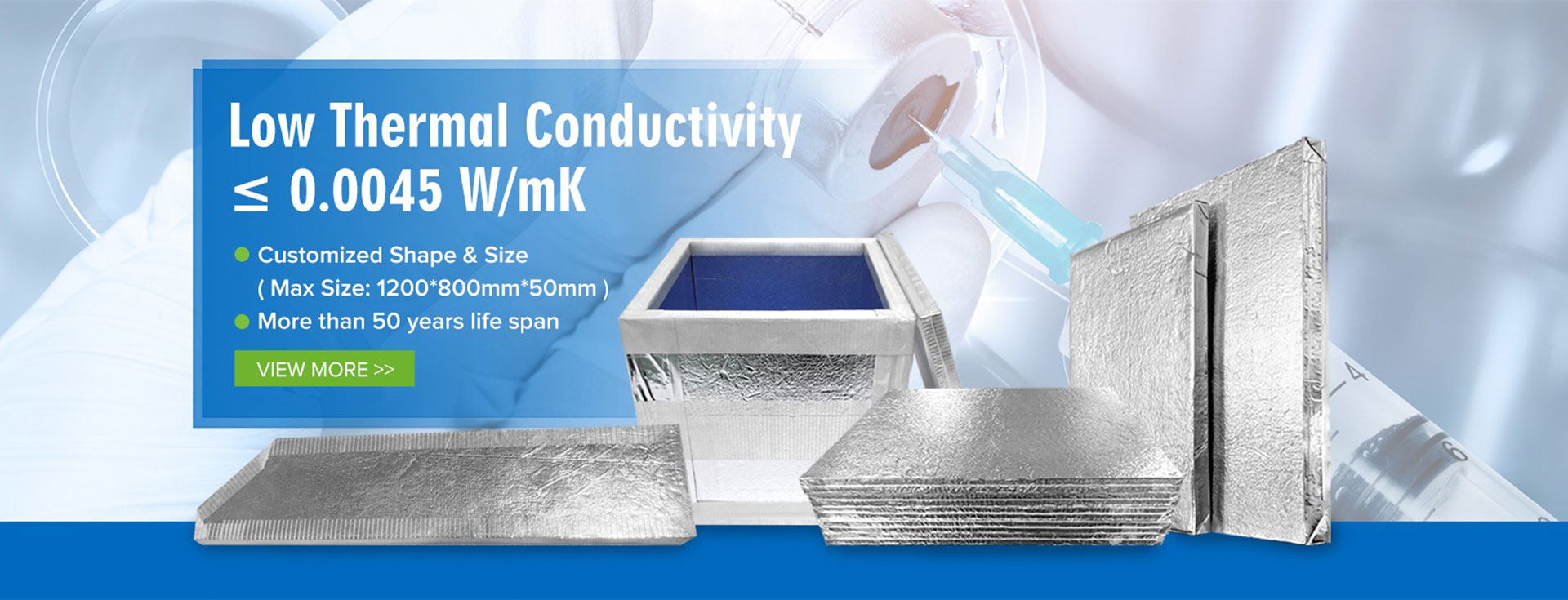

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Dec-27-2022