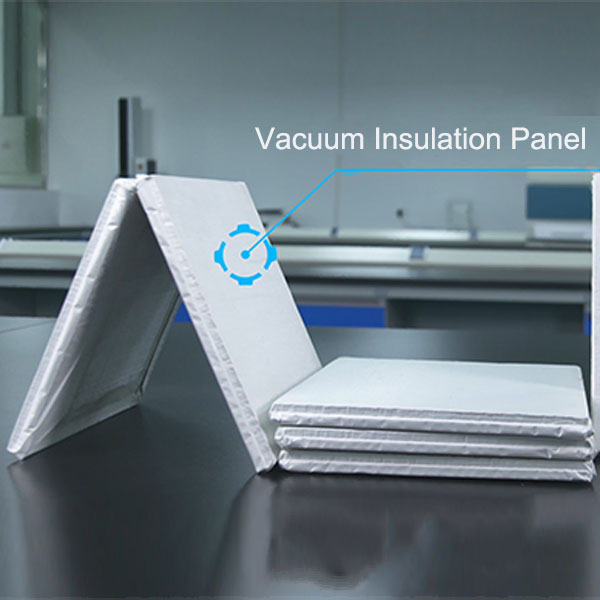

Do you know about vacuum insulation panels? They are increasingly popular in building construction as a way to increase energy efficiency and reduce heating and cooling costs. Vacuum insulation panels, or VIPs, are manufactured using advanced materials such as fumed silica cores, high temperature nano-panels and microporous insulation panels. These materials make the panels very effective in reducing heat loss and improving insulation. Let's take a closer look at how VIP is being used in the construction industry, and what future trends we can expect to see.

Manufacturers of fumed silica core materials have been working to improve the production process of vacuum insulation panels. They've been able to produce thinner panels while still maintaining their insulating efficiency. This means builders can use the panels in more areas of the building and create a higher R-value insulation system overall. High temperature resistant nano panel technology also allows VIP to be effectively used in roof and wall systems in high temperature environments such as industrial buildings.

The Microporous Insulation Panel factory has been producing VIPs for use in space-constrained areas. VIPs can be cut to size and shape, making them ideal for use in areas such as stud cavities or other confined spaces. These panels can also be used under concrete slabs, eliminating the need for traditional insulation, further improving the building's energy efficiency. Insulated roof shingles have become a popular choice for the roof of many buildings. The lightweight nature of VIP makes it easy to install and adds minimal weight to the roof, making it easier to build. In the construction industry, especially in commercial and industrial buildings, there is a growing trend of VIPs being used on roofs.

There are significant environmental and economic benefits to building vacuum insulation panels. They reduce the energy consumption of buildings, thereby reducing the environmental damage caused by carbon emissions. The reduction in energy consumption also results in lower energy bills for building owners, which is a huge long-term economic benefit. The use of VIP also leaves more space available for other building technologies, making it easier to construct buildings with more amenities, such as green roofs or solar panels.

In conclusion, VIP has become an important part of the building insulation system. They provide high-efficiency insulation while taking up minimal space and weight. We can expect to see more manufacturers and innovators come up with new technologies and processes to improve the production and application of VIPs. Building designers and building owners should start thinking about using VIP on their next project and understand the overall energy efficiency it can provide.

Zerothermo focus on vacuum technology for more than 20 years, main products: vacuum insulation panels, vacuum insulated glass, high temperature nano microporous panels, flexible insulation blanket mat. Zerothermo is committed to quality, innovation, and customer satisfaction makes them a trusted partner for businesses looking for reliable and efficient thermal solutions.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Mar-08-2023