External insulation falling off accidents often occur, especially in the past two years rock wool system falling off accidents。Exterior insulation system is the exterior component of the building, affected by cold, heat, humidity, weight, water, wind and other factors. On the other hand, the problem of building insulation quality can be said to be at the forefront of the wave, spend money to do insulation, please choose safe insulation materials! New energy-saving insulation material -- zerothermo buidling vacuum insulation panels, its fire, sound insulation, waterproof, environmental protection, energy saving and other advantages are indeed incomparable to other materials, in construction, industry and other thermal insulation field has a very wide range of uses, its thermal conductivity is lower than air (thermal conductivity of 0.006W/(M·K)), due to its own noncombustible characteristics, Dual functions of heat preservation and fire prevention, especially the weight of the material is very light, will not fall off and other accidents. In the current wall insulation market, cracking, falling off and fire accidents are common at present, such products should be said to have a wide range of application prospects.

The following depth analysis of the vacuum insulation panel is better than the traditional rock wool reasons:

Thermal Conductivity

Rock wool panel: 0.041-0.045W/ (m·K), and vacuum insulation panel: ≤0.006W/ (m·K), thermal conductivity is many times lower,also it has super insulation.

Fire Resistance Rating

Rock wool panel: A (non-combustible) and vacuum insulation panel: A (fireproof) fully meet the requirements of modern construction

Stability of System

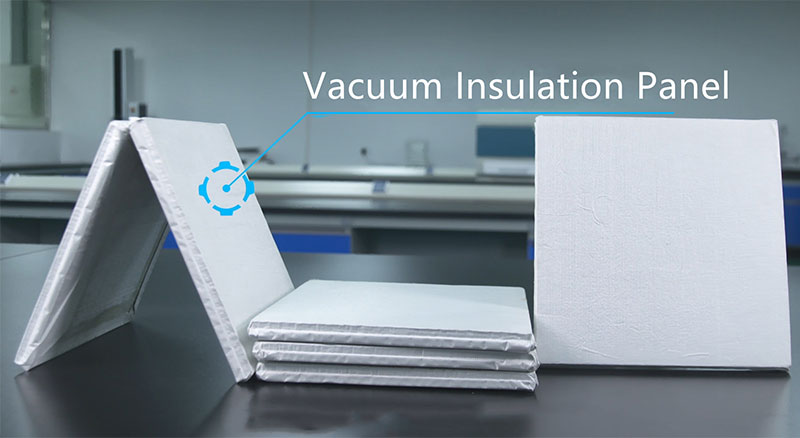

The VIP vacuum adiabatic plate produced by Zerothermo is based on the principle of vacuum adiabatic and nano microporous adiabatic. It adopts gaseous silica as the core material and is encapsulated in a high barrier film, and then made by vacuum process. The thermal insulation performance is 6 ~ 10 times that of traditional thermal insulation materials. No deformation due to the external environment; There is no cracking, bulging, shedding, water seepage phenomenon; Using edge sealing technology, there is no cold and hot bridge problem; The thickness is thin, the weight is light, the wall bearing is small and will not crack and fall off because of high temperature expansion in summer and cold closure in winter.

Meet the 75% Energy Saving Standard Requirements

The thickness of the rock wool panel is 80mm~100mm and the thickness of the vacuum insulation panel is 15mm~20mm, which largely saves the use of space in the building

Service Life

Rock wool panel: system stability is poor, difficult to work with the building life, and vacuum insulation panel: system stability is good, can work with the building life, usually can be used for more than 50 years

Energy Saving and Environmental Protection

The production process of vacuum insulation panel low power consumption, zero pollution and zero emissions, recyclable, easy to degrade, heat preservation and energy saving up to 75% energy saving standards

The Construction Process

It is difficult to plaster the surface, even if the interface agent is difficult to adhere, difficult to anchor, surface, deformation;The process is complex, the construction period, but the vacuum insulation panel unit area weight is light, the direct paste way, can shorten the construction period, save the cost.

Energy Saving and Environmental Protection

The production of rock wool panel has high energy consumption, environmental pollution and bacteria breeding, while the production process of vacuum insulation panel has low power consumption, zero pollution and zero emissions, recyclable, easy to degrade, heat preservation and energy saving can reach 75% or more energy saving standards.

Sichuan zerothermo Technology Co., Ltd. focuses on the application of new technology of energy-saving insulation materials and industrial alliance, customer-oriented, market-oriented, service is no small matter. Make your home more energy efficient, healthier, greener, environmentally friendly and comfortable.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Dec-14-2022