Glass manufacturing is an energy-intensive process, with about 75 to 85 percent of the energy consumed during the melting of glass. Reducing energy consumption at any stage of glass manufacturing can be beneficial in two ways: first, since energy is the most expensive consumable in the manufacturing process, saving energy can lead to direct savings; Second, in the manufacturing process, the higher the use of thermal efficiency, the more accurate control of the viscosity of the glass molten liquid. This makes product quality control easier, leading to further direct cost savings through waste reduction. So efficient refractories and thermal insulation materials are becoming more and more important in glass making equipment. In the past, glass kilns mostly used traditional thermal insulation materials, but there are generally high thermal conductivity at high temperature, energy saving effect is not ideal. With the increasing demand of energy saving, a kind of microporous insulation material is being used more and more in glass production.

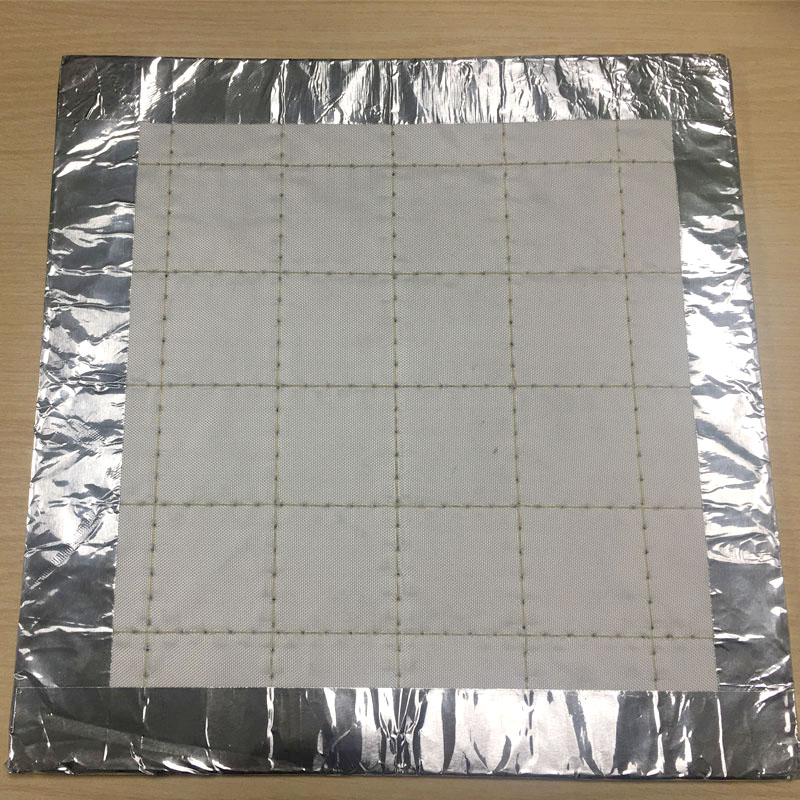

Microporous Insulation is a new profile material developed based on the principle of microporous insulation. The main components are ultrafine silicon oxide powder with a diameter of 7 to 12 nanometers, mixed thermal radiation shielding materials, and pressed by special technology. The surface of the product can be covered with glass fiber cloth, common forms are flat type, rolling type. Block type, soft blanket type, etc. Flat type can be used for flat furnace wall or large curved furnace wall, rolling type is mainly used for piping system. In the process of glass production, the main function of the microporous insulating plate is to reduce heat loss. Reduce energy consumption: improve the factory operating environment; Prolong the life of equipment to reduce the thickness of heat insulation layer, reduce the volume of equipment; Increase the internal volume. Reduce heat storage of insulation layer and increase heating rate

Heat loss needs to be carefully controlled throughout the glass making process to ensure optimal energy efficiency and minimal environmental impact. The most effective way to retain heat is to use a microporous adiabatic system, which has the following advantages:

The lowest thermal conductivity, its adiabatic efficiency is the traditional adiabatic material shaking several times

The lowest thermal conductivity, its adiabatic efficiency is the traditional adiabatic material shaking several times

It can be used in the production of various products with prefabricated products, and it can be pre-formed or easily cut and fixed at the installation site

The thinnest, lightest adiabatic system. The thickness of the insulation system is only a quarter of the thickness of the traditional insulation material

No inhaled fiber, completely harmless, environmentally friendly. Safe and clean to use, in line with international safety and health norms

Capable of continuous and stable operation at 800 °C -1000°C. With negligible linear shrinkage at maximum temperature, good recycling performance, no damage.

Due to the continuous maturation of the application technology of nano microporous heat insulation materials, the successful application in some glass factories in recent years has proved that the material has a remarkable effect on energy saving and emission reduction. Although compared with traditional heat insulation materials, the initial investment cost will be increased to a certain extent, but the later reduction of energy consumption benefit is significant, considering the long-term benefits brought by energy conservation and emission reduction, such investment is worthwhile. It is foreseeable that under the background of increasing requirements for energy conservation and emission reduction, the application of nano-porous heat insulation materials in the glass industry will be more and more popular.

Zerothermo focus on vacuum technology for more than 20 years, our main products : vacuum insulation panels based on fumed silica core material for vaccine, medical, cold chain logistics, freezer, integrated vacuum insulation and decoration panel, vacuum glass, vacuum insulated doors and windows. If you want to learn more information about Zerothermo vacuum insulation panels, please feel free to contact us, also you are welcome to visit to our factory.

Sale Manager: Mike Xu

Phone :+86 13378245612/13880795380

E-mail:mike@zerothermo.com

Website:https://www.zerothermovip.com

Post time: Feb-23-2023